Precision Colour Inspection and Measurement

Accurate colour and surface analysis is critical in industries where product appearance defines quality, brand value or compliance with strict production standards. Traditional colour measurement tools can provide only limited information, often missing subtle variations in shade or tone that can influence performance and consumer perception.

Hyperspectral imaging captures hundreds of spectral bands across the visible and near-infrared range that deliver detailed spectral information for every pixel of the target. This allows for precise, objective and repeatable measurement of colour, brightness, gloss and surface properties.

Key Benefits of Hyperspectral Imaging for Colour & Surface Characterization

- True Colour Accuracy: Detect even the slightest deviations in shade or tone for consistent product quality.

- Surface Analysis: Characterize gloss, coatings, and surface treatments with spectral precision.

- Defect Detection: Identify scratches, stains, and uneven coatings that compromise product value.

- Non-Destructive Testing: Inspect samples without altering or damaging them.

- Process Optimization: Integrate real-time hyperspectral monitoring into production lines to ensure uniformity and reduce waste.

Display & Screen Inspection

Modern display technology, such as LCD, OLED, MicroLED and QLED, are central to consumer electronics, automotive interfaces, medical devices, and industrial equipment. Ensuring that displays meet standards for brightness, colour accuracy, uniformity and defect-free performance is critical for end-user satisfaction and brand reputation.

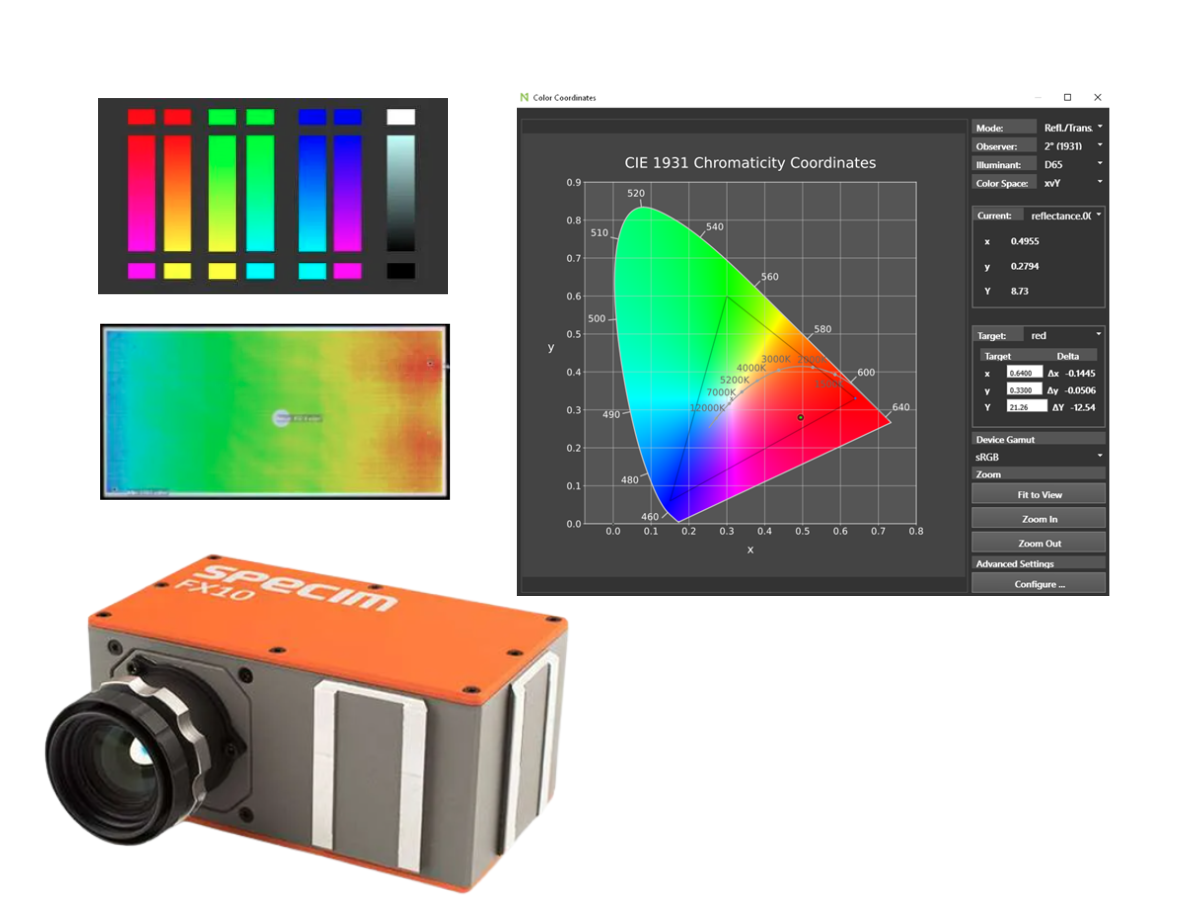

VNIR hyperspectral cameras, such as the Specim FX10 and Specim IQ, make it possible to measure colour, luminance, reflectance and uniformity with unmatched precision, enabling manufactures to quantify display performance with scientific precision, ensuring their products meet both technical specifications and consumer expectations. It can also be used to reliably detect micro-defects such as mura, pixel defects and surface scratches.

This not only enhances reliability and reduces consumer returns, but also gives brands a competitive advantage in delivering the highest quality next-generation display technologies

Common Applications:

- Consumer Electronics: Quality control for smartphones, tablets, laptops and TVs

- Automotive Displays: Ensuring visibility, consistency and reliability of in-vehicle displays under varying conditions

- Aerospace & Defense: Validate ruggedized and mission-critical displays under stringent performance requirements

- High-End Industrial & Professional Displays: Precision applications such as broadcasting, simulation and design

Colour Control in Digital Printing

In digital printing, colour fidelity and print consistency and critical in meeting client expectations, protecting brand identity and reducing costly reprints. Even small deviations in shade, gloss, or ink coverage can result in subpar output.

Traditional colour control methods, such as spot analysis with spectrophotometers, provide limited sampling and can overlook subtle but important variations across the entire print area.

Hyperspectral imaging, using high-quality industrial VNIR systems such as the Specim FX10, deliver full-field spectral analysis for every pixel of the printed material, delivering detailed colour and surface information that goes far beyond conventional colour management systems using RGB or multispectral sensors. This enables printers to measure, monitor and correct colour and quality issues in real-time.

Common Applications:

- Commercial & Packaging Printing: Ensure exact reproduction of brand colours and logos

- High-resolution Graphic Arts: Validate fine details, gradients and special effects printing

- Textile Production: Monitor dye sublimation and fabric printing quality

Automotive & Industrial Coatings

In the automotive, aerospace and industrial manufacturing industries, coatings and surface finishes are more than just aesthetic, they deliver protection, durability and brand identity. Producers must deliver on appearance, as well as consistency, efficiency and traceability. Conventional inspection methods, such as visual checks, RGB cameras or point spectrometers, are limited in accuracy, sensitivity, spatial coverage and ability to detect subtle or hidden defects.

Hyperspectral imaging technology addresses these challenges by combining high-resolution imaging with detailed spectral data, enabling objective, non-contact and full-field analysis of coatings in real time. Hyperspectral cameras, such as the Specim FX10, ensure precision colour matching based on full spectral reflectance rather than a single colour value, acrosss batches, substrates and suppliers.

Hyperspectral imaging can also be used to evaluate thickness and uniformity in automotive paint or protective coatings to ensure corrosion resistance

Common Applications:

- Automotive Manufacturing: Paint quality inspection, defect detection, colour consistency and multilayer coating validation

- Aerospace & Defense: Monitoring protecting coatings for aircraft fuselage and components for performance and safety

- Industrial Machinery & Equipment: Surface finish verification for protective and functional coatings (anti-corrosion, anti-wear, thermal)

- Consumer Goods & Applications: Visual uniformity and durability in electronics, appliance and furniture coatings