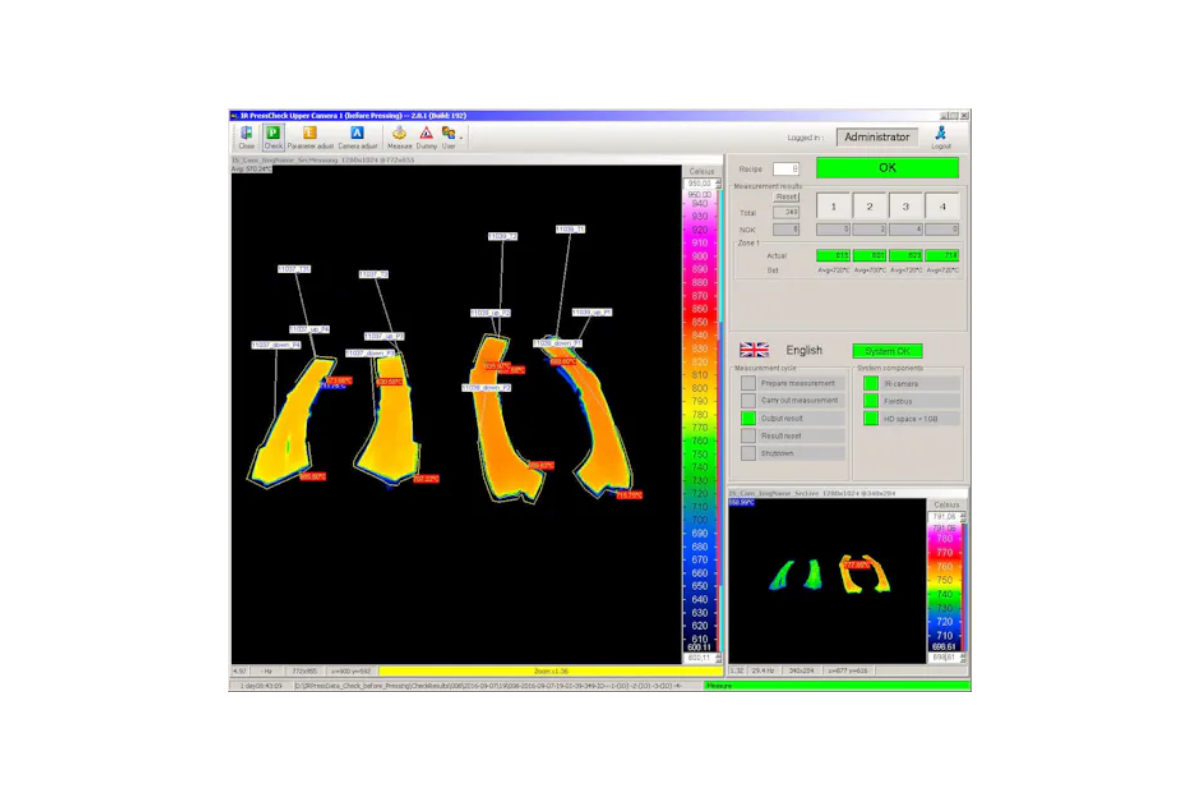

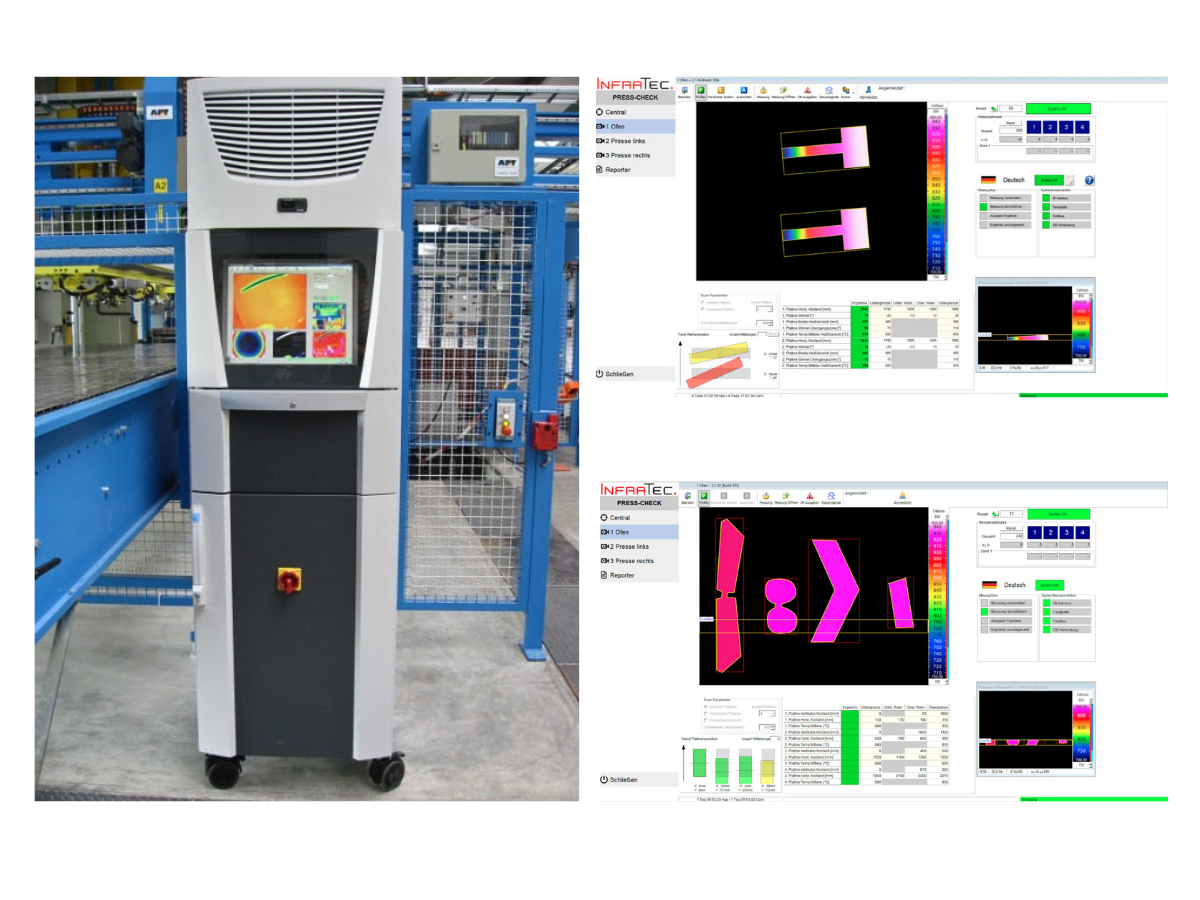

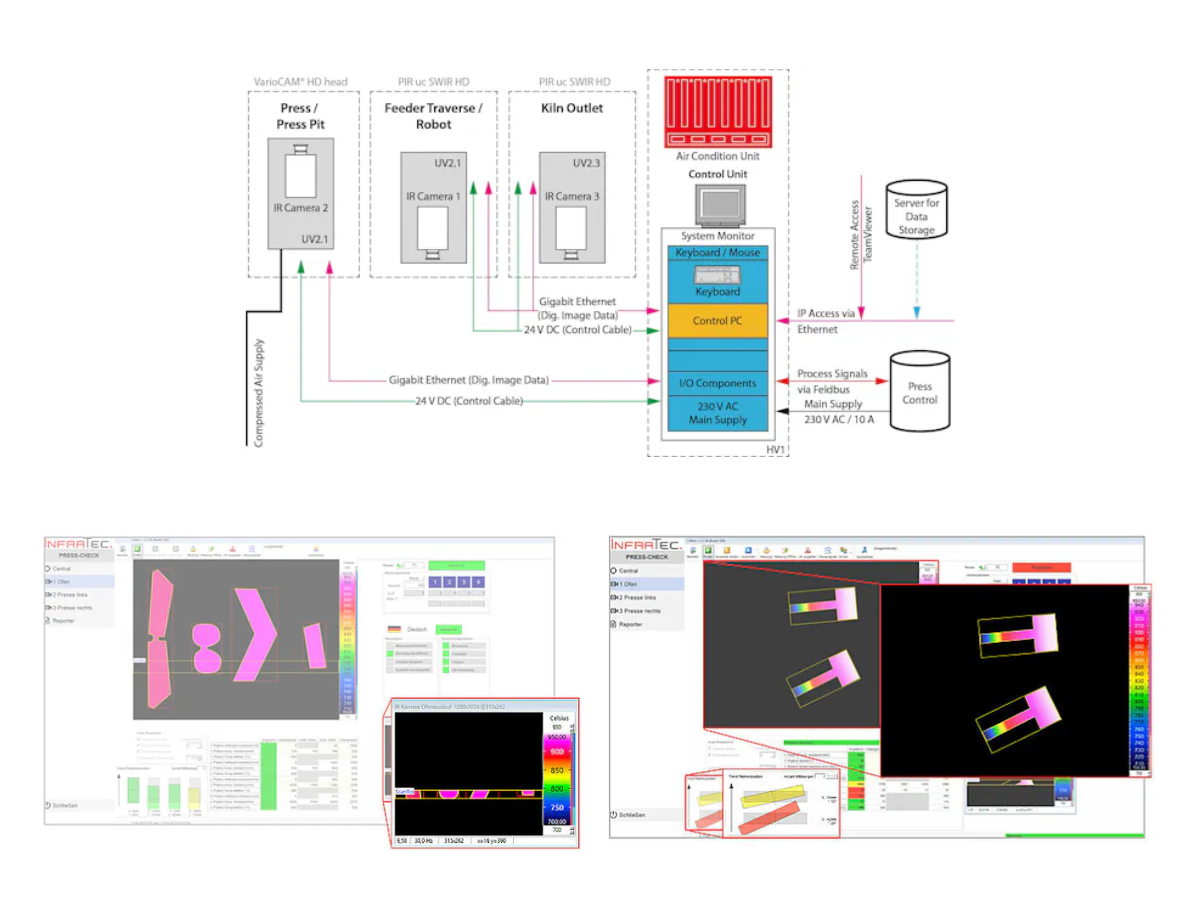

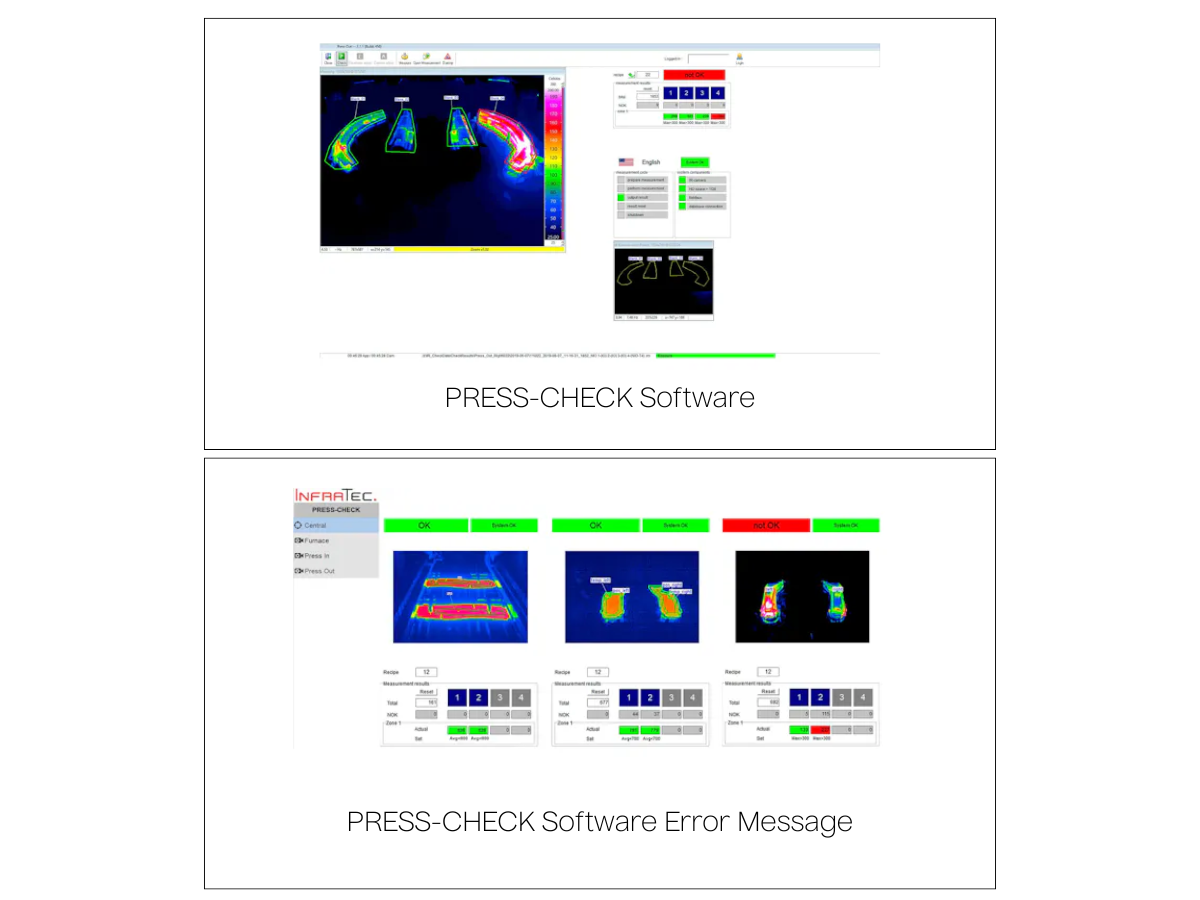

The PRESS-CHECK System software provides a complete, end-to-end platform for parameter setting, monitoring, operation, visualization, evaluation, and reporting, supporting both manual and fully automatic test modes for temperature, load, and position control.

The intuitive user interface enables easy parameterization, setup, and management, while robust data and recipe management ensure consistent, repeatable operation.

Seamless integration with supervisory control and quality management systems allows for automatic data transfer and reporting. Inline, scene-based geometric and thermal characterization of heat-treated sheet metal blanks at the furnace exit enables reliable detection of components, even when only partially visible, with automatic adaptation to variable process speeds.

Dynamic, on-the-fly measuring fields (ROIs) are generated based on component recipes to capture precise position and temperature data, while statistical analysis of positional information supports automatic adjustment of furnace loading. Multi-zone components and their transition zones are detected and measured both geometrically and thermally, ensuring stable processes and high-quality hot forming and press-hardening results.