INDU-SCAN Key Benefits:

- Modular system: Up to three high-resolution infrared cameras can be used

- Value for money: A cost-effective and reliable solution

- Durable: High-quality industrially tested components for fault-free operation 24/7

- Easy configuration: Separately for camera and control unit

- Extensive reporting: Detailed event logs for downstream analysis

- Easy configuration: Separately for camera and control unit

Ideal Solution For:

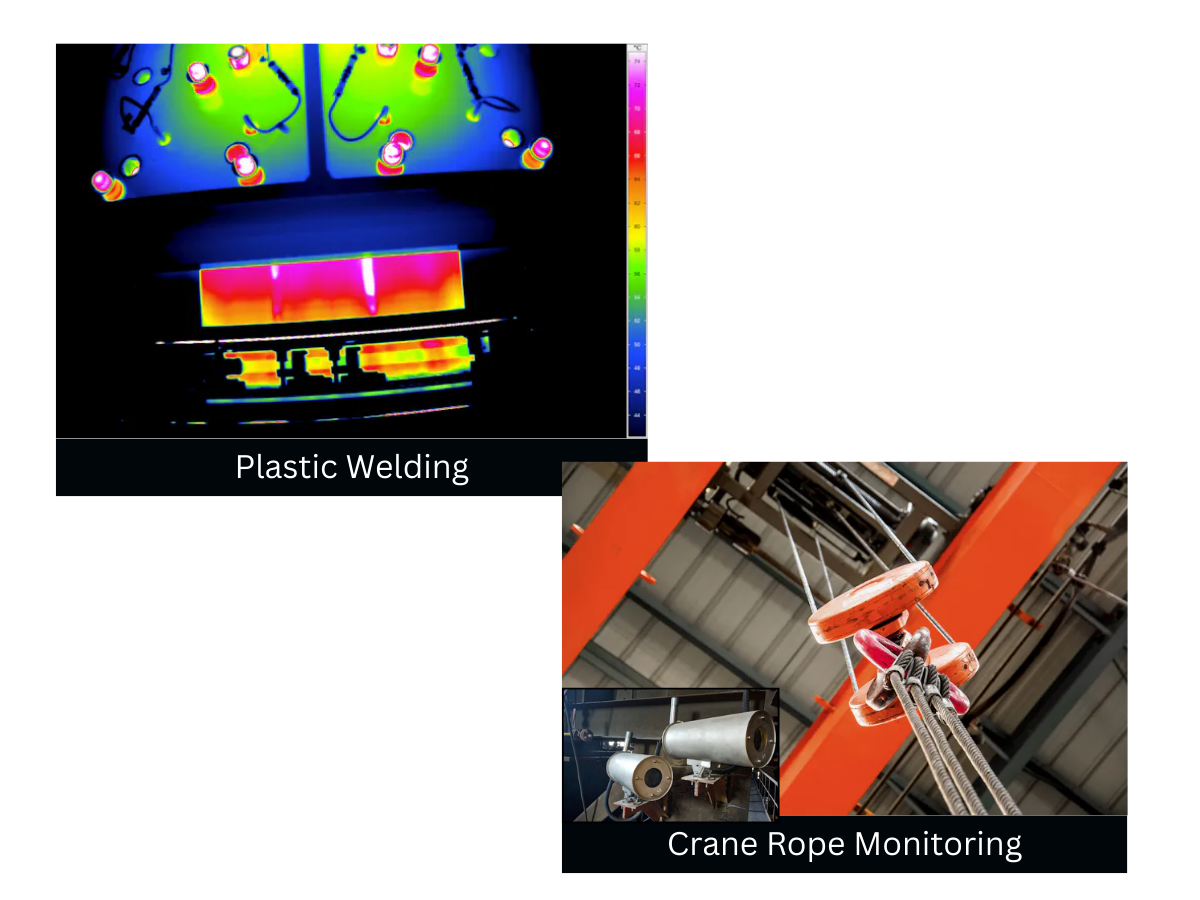

- Plastic Welding

- Crane Rope Monitoring

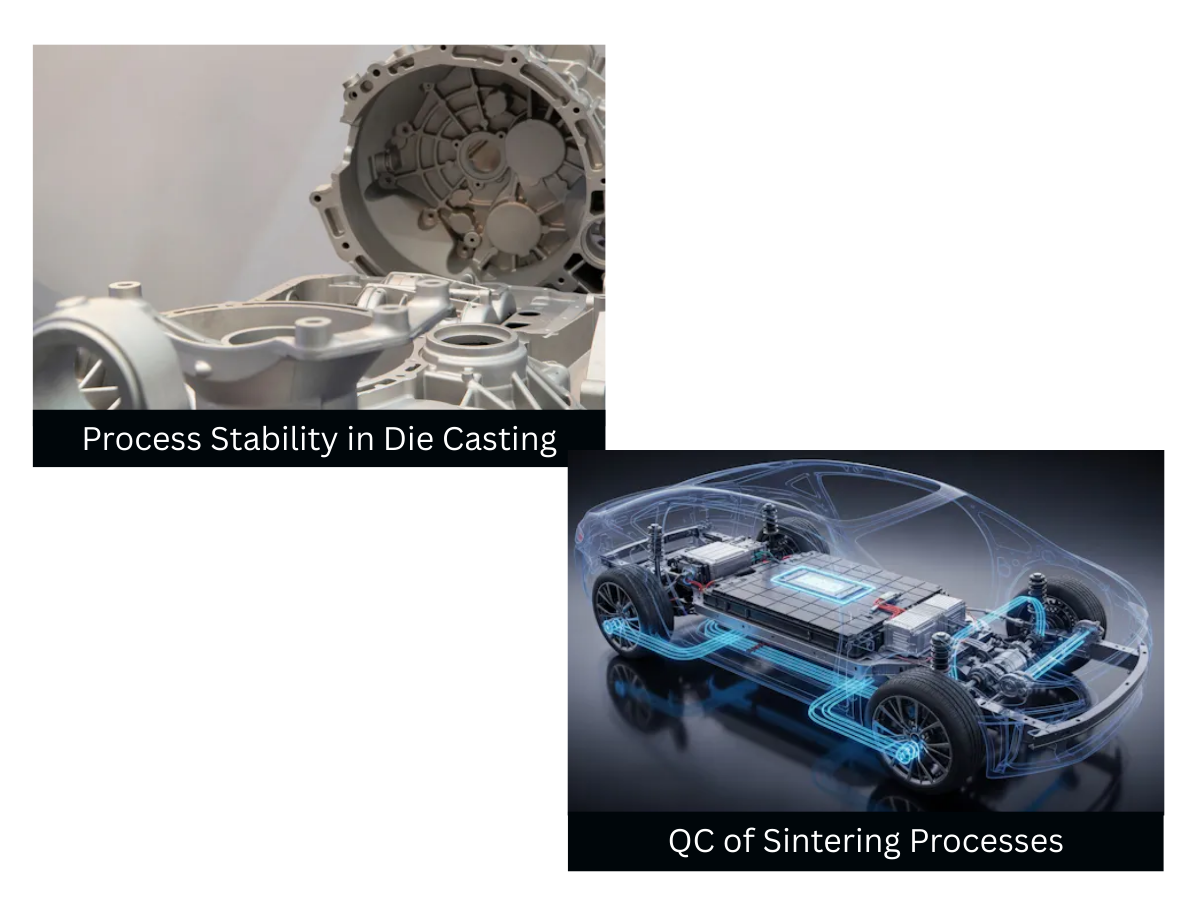

- Die Cast Monitoring

- Film Seal Defect Detection

- Sintering Monitoring

- Quality Control of Metal Sheet Joints

The scope of INDU-SCAN 4.0 includes

- Professional pre-analyses and selection of camera heads and optics according to strict technical measurement criteria of the inspection task

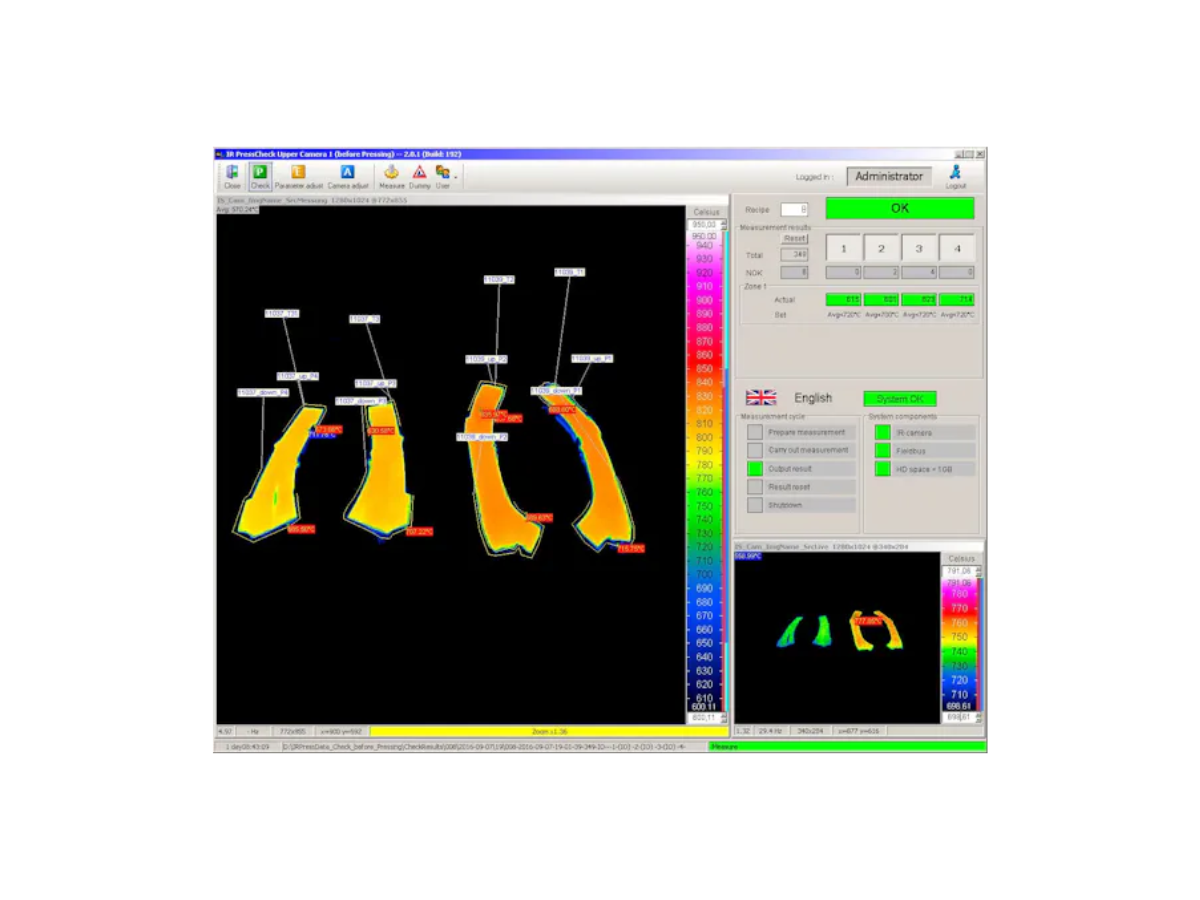

- Recognition of components and their spatial location (machine learning) as the starting point for simultaneous, partially multi-stage multi-spot analysis

- Positioning of components using various algorithms

- Transformation of non-linear thermal signatures and heat flows using state-of-the-art software tools incorporating experience-based algorithms

- Technical implementation based on a flexible hardware and software kit for fast integration of customer-specific requirements

- Application of powerful, industrially proved components, that are capable of continuous use

- Selection between thermographic cameras of different performance classes and spectral ranges, application-specific protective housings and modular system control units

- Individually configurable system software for smooth interaction of all components